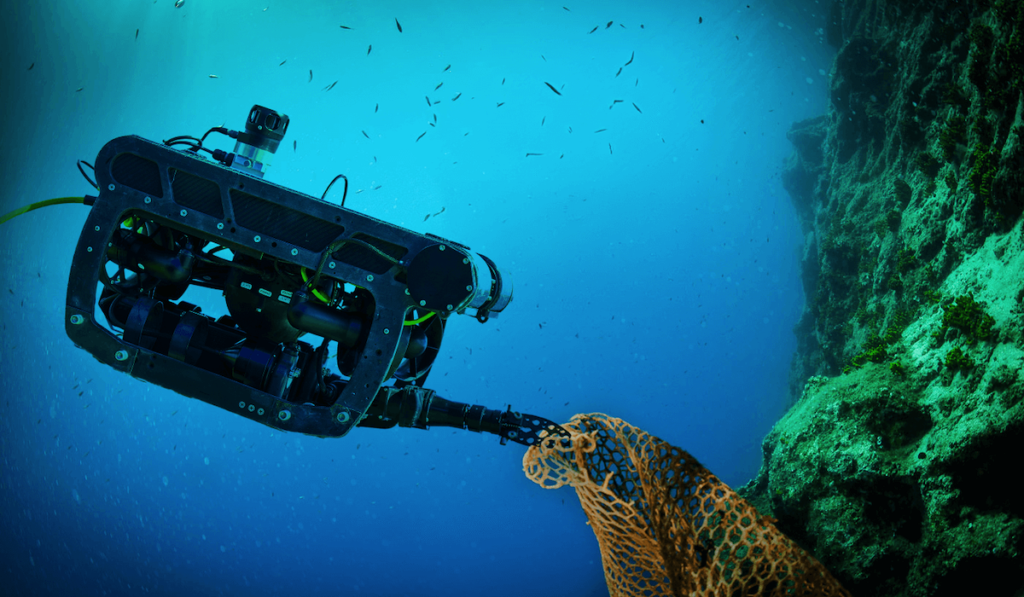

Deep Trekker provides remotely operated vehicles (ROVs) for offshore operations, offering crucial support for underwater inspections, maintenance, environmental monitoring, asset management, and more.

Deep Trekker ROVs are engineered for harsh conditions, offering maneuverability, rapid deployment, and ease of use, making them ideal for offshore tasks. These ROVs can enhance inspection accuracy and efficiency, lower operational costs, and provide a safer alternative for underwater tasks in offshore maritime applications.

PHOTON

The PHOTON is a lightweight mini observation-class ROV, designed for confined and hard-to-reach areas, enhancing inspection safety and efficiency. It operates at depths of 120 meters and features an ultra-HD camera with a rotating head, bright LED floodlights, and up to 300 meters of tether options.

PIVOT & REVOLUTION

For tasks requiring greater payload capacity, deeper dives, and modular features like sonar imaging, the PIVOT and REVOLUTION models provide extensive capabilities. Equipped with six vectored thrusters, these models offer superior stability and maneuverability. Their features include intelligent sensors, a 200-degree rotating ultra-HD 4K camera, BRIDGE integration, and modular tool add-ons, making them well-suited for demanding environments.

Underwater ROV Offshore Applications in Maritime Operations

Oil & Gas Inspections

Offshore energy inspections are essential for detecting potential issues before they escalate, preventing severe failures and environmental hazards. Proper inspections ensure safe, efficient, and responsible energy production while maintaining infrastructure integrity and safeguarding human lives and ecosystems.

Managing offshore assets and infrastructure is inherently complex, hazardous, and costly. As a result, underwater ROVs have become the industry standard, offering distinct advantages over conventional inspection methods. They eliminate the need for scaffolding, sky-lifts, cherry pickers, and costly helicopter aerial views. Furthermore, ROVs reduce the necessity for inspectors to enter hazardous environments, such as confined ballast tanks or high-risk diving situations.

Platform & Rig Inspections

Oil platforms are intricate structures designed to endure extreme conditions, requiring routine inspections to maintain their structural integrity, operational efficiency, and safety. ROVs play a key role in detecting rust, corrosion, and other potential hazards that could lead to serious incidents. ROVs are deployed to inspect various offshore platform components, including:

- Platform legs

- Mooring systems

- Risers

- Cooling and ballast tanks

- Flare stacks

- Gas emissions in confined spaces

- Wellheads

By using ROVs, operators can efficiently detect leaks, minimize environmental risks, and respond swiftly to emergencies.

Pipeline Inspections

Offshore pipelines stretch across the seabed for vast distances, while risers connect the seabed to surface platforms. These components are susceptible to corrosion and damage, necessitating regular monitoring for safe and efficient operations. Traditionally, inspections required divers, making the process expensive and time-consuming.

ROVs offer a streamlined alternative, significantly reducing both inspection time and costs. A single operator can deploy an ROV and complete an inspection in hours, whereas diver-based assessments may take weeks. Additionally, using ROVs eliminates risks associated with human diving, enhancing overall safety.

FPSO Inspections

Floating Production Storage and Offloading (FPSO) units, which process and store oil and gas in deep waters, require consistent inspections to ensure operational safety. ROVs provide a cost-effective and efficient alternative to dry-docking and diver inspections.

ROVs conduct thorough underwater hull inspections, identifying biofouling, cracks, structural defects, corrosion, and coating conditions. They also assess FPSO components such as rudders, propellers, and confined spaces like sea chests and ballast tanks. By reducing the need for divers in hazardous conditions, ROVs improve safety and lower accident risks.

Site Exploration

Underwater ROVs support oil and gas exploration by evaluating potential drill sites, delivering real-time data, and reducing preparatory requirements. They conduct seabed surveys and sampling to determine site viability.

This information is crucial for assessing geological and environmental conditions, mapping underwater terrain, identifying hazards, and analyzing sediment composition. Sample collection allows geologists to assess hydrocarbon reserves and evaluate potential environmental impacts. Conducting detailed assessments ensures drilling operations are performed in viable and secure locations, reducing the likelihood of costly setbacks and environmental damage.

Subsea Construction & Maintenance

ROVs conduct pre-dive checks to verify site conditions before divers enter and monitor divers during operations for added safety. During underwater equipment, pipeline, and cable installations, ROVs assist with precise placement, ensuring correct positioning and secure attachment. They also provide real-time site data, aiding in accurate project estimates.

For subsea maintenance, ROVs offer significant benefits. They stabilize equipment during repairs, navigate confined spaces inaccessible to divers, and perform temporary fixes until permanent repairs can be scheduled. These capabilities minimize downtime and disruptions, ensuring continuous and safe operations.

Wind Energy

Offshore wind farms are projected to expand their contribution from less than 0.1% to 15% of global energy production by 2050, as noted in the 2023 World Energy Outlook Report. This growth necessitates efficient and cost-effective inspection methods.

With turbine blades exceeding 200 feet in length, inspections pose challenges due to size and limited accessibility. ROVs address these challenges by capturing comprehensive images of the turbine structure. Their ability to detect internal corrosion, cracks, and other issues supports proactive maintenance schedules and reduces the need for inspectors to enter hazardous areas.

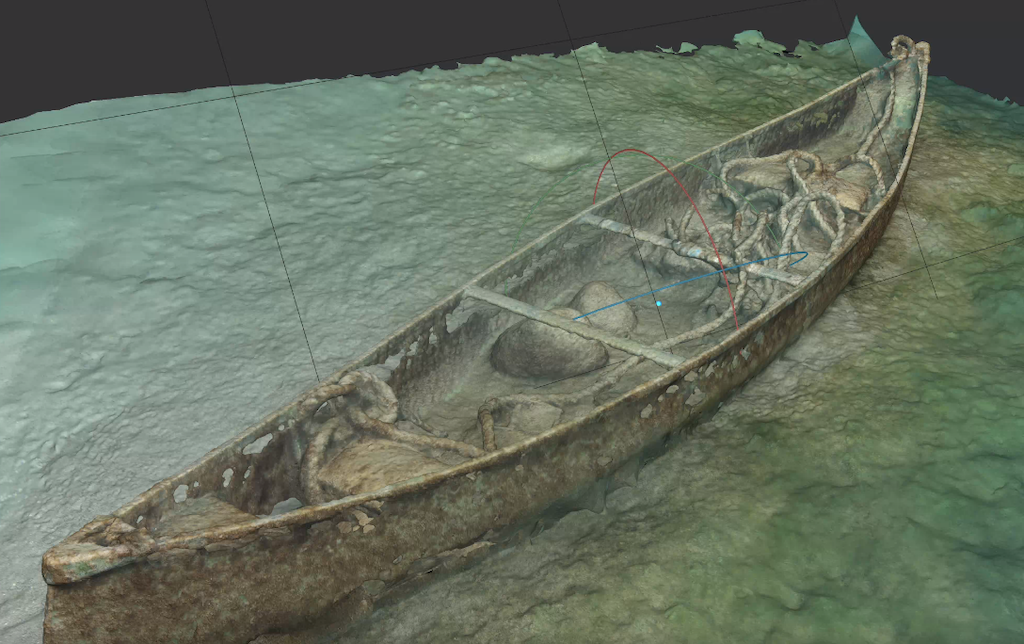

Maritime Archaeology

ROVs assist in locating submerged historical sites with precision, capturing detailed images and videos of artifacts often inaccessible due to depth or environmental conditions. By providing close-up views of shipwrecks and relics, they help archaeologists assess site conditions and develop preservation strategies.

ROVs also generate 3D models of archaeological sites using photogrammetry, capturing high-resolution images from multiple angles. These models facilitate detailed examinations, provide permanent records, and help monitor structural changes over time, supporting cultural heritage preservation.

Search & Recovery

ROVs play a critical role in locating and, when feasible, recovering missing individuals and objects, such as boats, planes, and submarines. Equipped with high-resolution cameras and advanced sensors, ROVs navigate challenging underwater environments, making them indispensable for searches where traditional methods may be limited.

Additionally, ROVs collect crucial evidence and data, aiding investigations by providing real-time visual documentation. Their use enhances recovery efforts, increases accuracy, and improves safety for first responders.

Environmental Monitoring

Environmental monitoring is a key aspect of offshore operations due to the potential risks energy production poses to marine ecosystems. Equipment failures can lead to significant environmental damage, making regular inspections essential.

ROVs enable detailed offshore infrastructure assessments, helping operators detect leaks, cracks, corrosion, and spills before they become severe issues. By identifying problems early, ROVs help maintain structural integrity and reduce the likelihood of environmental incidents.

Additionally, ROVs contribute to ecological monitoring by evaluating marine species and habitats, conducting water and sediment sampling, analyzing water quality, and performing seabed surveys. They also assist in recovering lost fishing gear and assessing the environmental effects of commercial shipping.

Advantages of ROVs in Offshore Operations

Utilizing underwater ROVs for offshore inspections is transformative. Traditional methods are often complex, expensive, and hazardous, but technological advancements have simplified these processes, making them safer, more efficient, and cost-effective.

Key benefits of ROVs in offshore energy inspections include:

- Cost reduction – Minimizes the need for commercial divers, specialized equipment, and helicopter scheduling.

- Enhanced safety – Performs hazardous tasks and collaborates with divers to reduce exposure to dangerous conditions.

- Increased efficiency – Conducts inspections faster than divers, deployable at any time without requiring system shutdowns.

- Improved data recording – Equipped with cameras and data logging software, ROVs enable precise inspection reports and asset status tracking for better maintenance planning.

- High-quality imaging – Features 4K cameras with color correction, turbidity filtering, digital zoom, sonar, and location mapping for low-visibility conditions.

- Modular functionality – Supports add-ons such as manipulators, ultrasonic thickness gauges, and cathodic protection probes for comprehensive data collection.

Investing in an underwater ROV can significantly reduce operational costs while delivering precise and consistent data, enhancing efficiency and safety in offshore operations. These systems protect critical infrastructure and create safer working conditions for offshore personnel, ensuring long-term benefits for the industry.