D-2 Inc. is streamlining the manufacturing process for its conductivity, temperature, and depth (CT/CTD) sensors by optimizing production efficiency and maintaining a stock of critical components that typically have long lead times.

These improvements have significantly reduced delivery times, ensuring that oceanographic researchers receive their equipment faster. By addressing these challenges, D-2 Inc. is helping researchers meet tight deployment schedules without delays caused by extended lead times.

CTD Lead Times for Oceanography

The oceanographic community studies the Earth’s oceans, gathering essential data that contributes to a deeper understanding of oceanic and climatic processes. Researchers deploy CTDs and CT sensors on research vessels and other platforms to measure salinity, pressure, and temperature.

Given the high costs and strict schedules associated with oceanographic expeditions, timely equipment delivery is critical. Delays in obtaining or calibrating CTDs can disrupt research timelines, potentially leading to costly postponements.

D-2 Inc. has reportedly engaged with oceanographers at numerous industry conferences, where one recurring concern has been the long lead times for CTD orders and calibrations. Many researchers have reported that obtaining CTD sensors or having them calibrated within a reasonable timeframe is a major challenge.

Industry feedback indicates that some manufacturers require more than 14 weeks to fulfill new equipment orders or complete calibrations, creating significant logistical issues for research teams working on scheduled deployments. Recognizing this problem, D-2 Inc. has taken proactive steps to offer a more efficient solution.

New CTD & CT Delivery Times

By refining its manufacturing processes and maintaining inventory for long lead-time components, D-2 Inc. has reduced CTD and CT delivery times from the industry standard of 12-16 weeks to just 4-8 weeks. Standard configurations can be completed in as little as four weeks, making D-2 Inc. one of the fastest providers of CTDs and CT sensors globally.

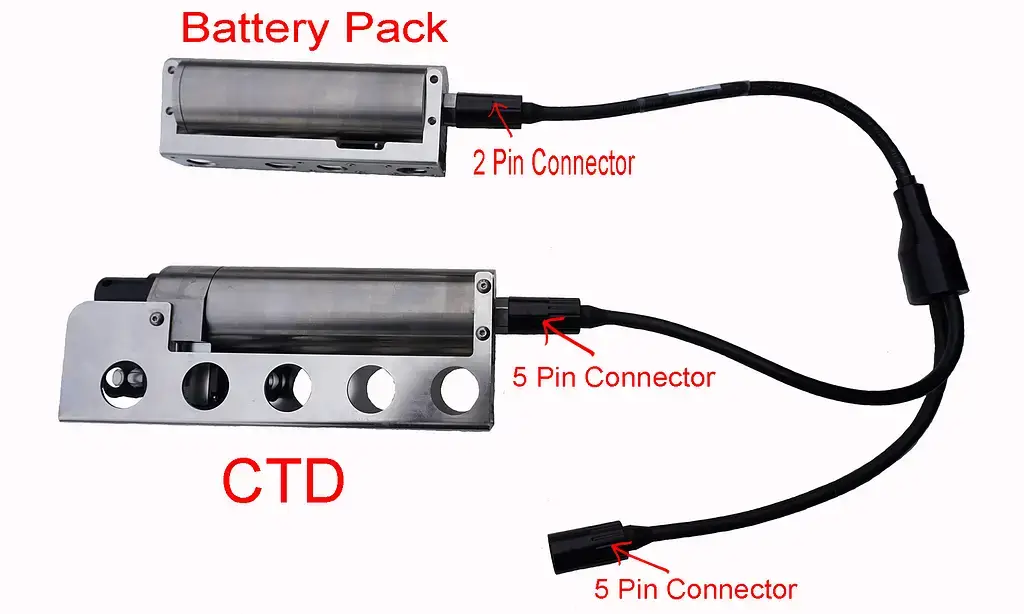

D-2 Inc. offers a comprehensive range of CTD sensors. Since salinity measurements rely on conductivity and temperature data, these sensors are crucial for accurate oceanographic research.

D-2 Inc.’s closed-field sensor design ensures high accuracy without requiring additional calibration, allowing for immediate deployment across various research platforms. The company’s compact, low-power designs utilize flow-through measurements, further enhancing efficiency.

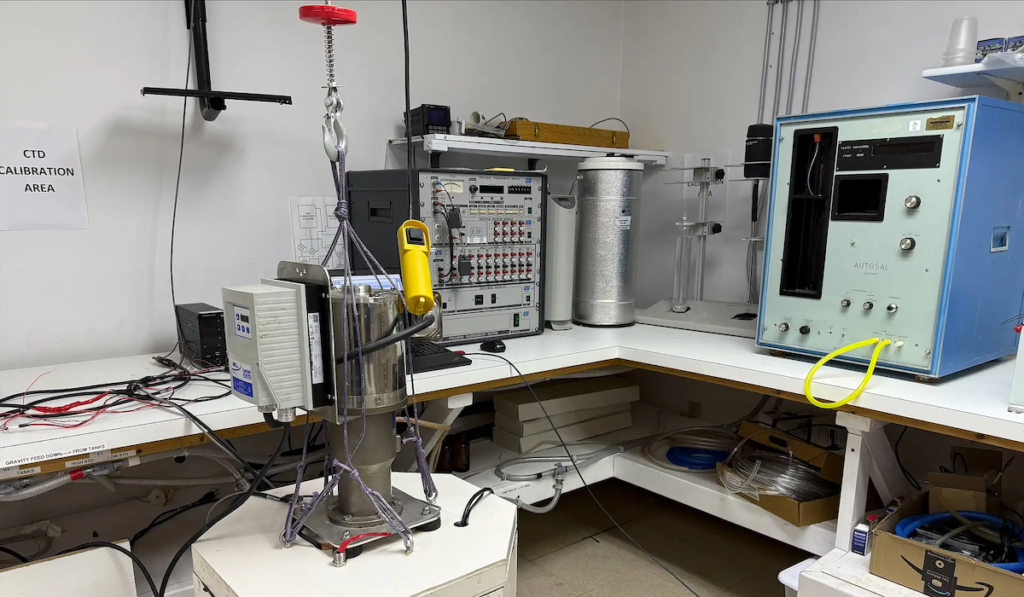

Accurate & Rapid CTD Calibration Lab

D-2 Inc. has also enhanced its calibration capabilities by upgrading its laboratory with a salinometer and a temperature standard, ensuring highly accurate calibrations with NIST traceability using TEOS-10 for calculations. As a result, D-2 Inc. can now calibrate CTDs and CT sensors within two weeks of receiving the unit.

Located on Cape Cod, D-2 Inc.’s calibration facility offers a strategic advantage for research teams operating in the North Atlantic. Currently, the company provides calibration services exclusively for its own equipment, but future plans include expanding services to all CTD sensors.